It’s no secret that Huddersfield has long been renowned as home to the world’s finest cloth, but is the knowledge of and passion for this once-booming trade still existent today, or is the legacy unravelling over the course of time? Local, industry experts – including Dugdale Bros – recently offered their thoughts to Huddersfield Examiner on where the textiles revolution all began, why it became so woven into the social fabric of this Yorkshire town, and where it currently lies in modern-day society…

Where has all the knowledge of Huddersfield’s clothmaking heritage gone?

The Industrial Revolution in the nineteenth century was a catalyst for the flourishing textiles trade that ensued in Huddersfield. And because of the town’s unique geography, the region’s water provided optimum conditions for washing wool.

Consequently, almost all impurities are filtered out by the limestone hills of the Pennines, allowing the fibres to retain the lustrous quality and soft handle, for which they are internationally celebrated.”

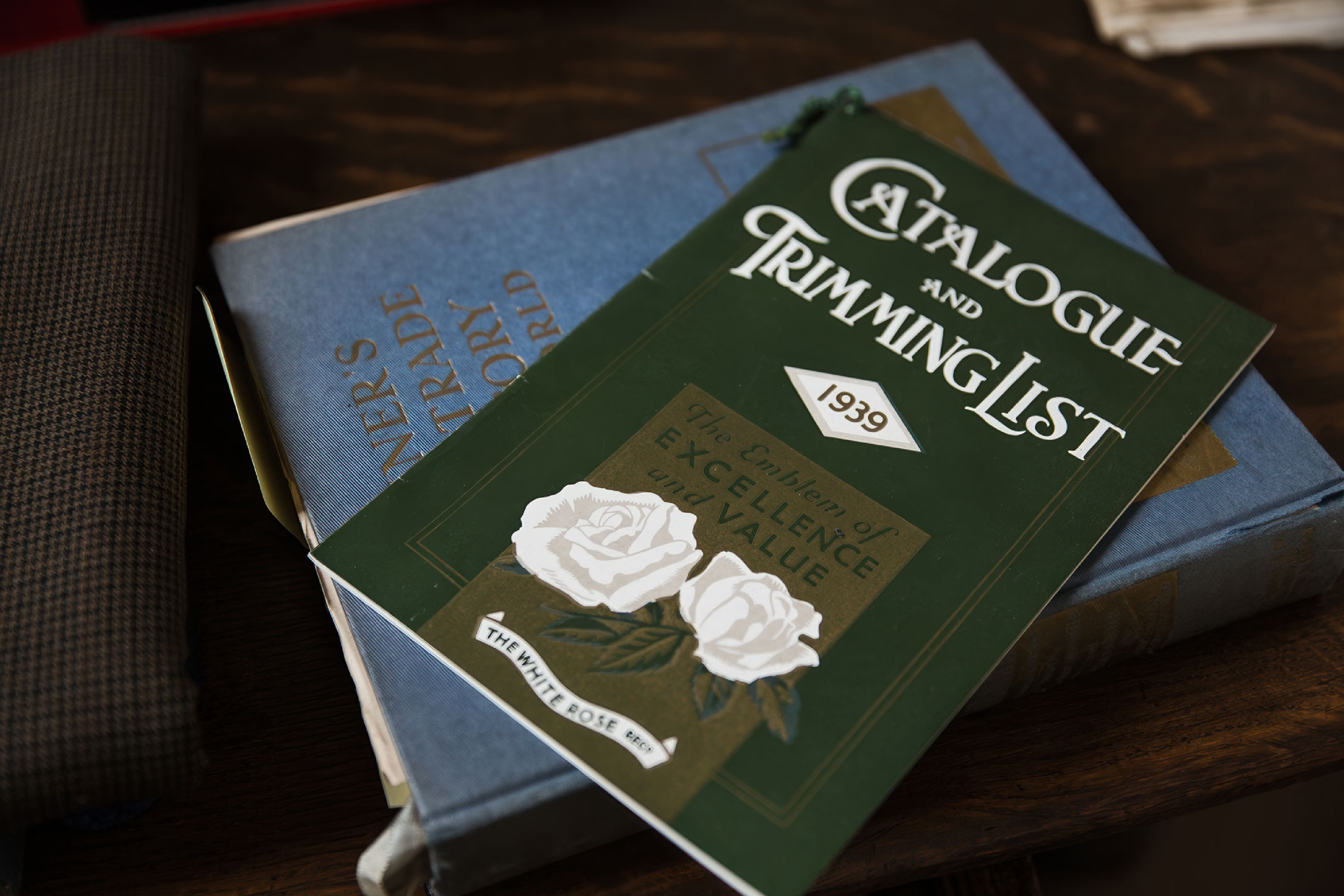

Housed in a Victorian building on Northumberland Street – known locally as ‘The Towers’ – Dugdale has been collaborating with trusted spinners, weavers, dyers and finishers stationed within a 20-mile radius of its base, since its beginnings in 1896.

Over this 123-year period, Dugdale has supplied premium-quality cloth to tailors, designers and luxury fashion houses across the globe – with the brand’s ‘Made in Huddersfield’ selvedge being a mainstay within many cutting rooms on Savile Row.

Simon elaborated: “For sartorial professionals, Huddersfield is regarded the Mecca of cloth and yet the majority of the UK population is unaware of this.

“Over the last 12 months, there’s been a resurgence in demand for more robust and characterful worsted cloths that are produced here, to such an extent that the town’s looms can’t produce fabric fast enough.”

Simon went on to add: “There are ways to express yourself other than garish, synthetic linings or coloured button holes, and characterful Huddersfield cloth is becoming the first choice for more and more people entering this market.

“There’s now a new generation of young men and women who are realising that made-to-measure garments offer a better way for them to display their individuality.”

When asked what role he sees the industry playing in modern society, Simon explained: “Industry knowledge hasn’t disappeared, it’s just a little more ensconced in modern-day habits and attitudes. But the surge in business shows that people’s interest in high-quality clothing, local history and provenance is still re-emerging.”

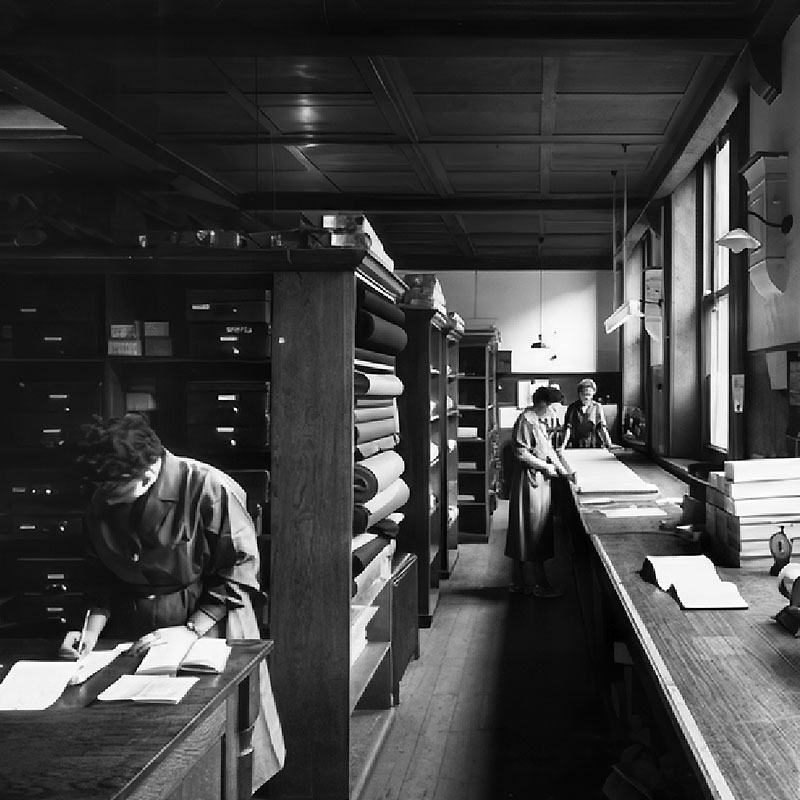

Gordon Kaye – previously MD of Taylor and Lodge and ex-Chairman of the National Wool Textile Export Corporation – is one of Huddersfield’s most established names in the sector and provided some historical context: “When industry decline began in the late 1960s and early ‘70s, the clothmaking scene changed dramatically. Technology and automation replaced a lot of the skilled manpower previously used in the hundreds of mills situated in Huddersfield and the surrounding Valleys.”

He then went on to echo Simon’s sentiments: “Most of the knowledge nowadays is in old hands and old heads, but there are still pockets of interest in this traditional craftsmanship being shown by younger generations, which is very heartening to see.

“Every year, we host a textile gathering at Huddersfield Rugby Union Club in Lockwood, where faces – old and new – gather to discuss all-things cloth. From old mill workers to contemporary designers, it’s a space where expertise is shared and valued.”

However, another strand of the sartorial story in answering whether there is a deficiency in textile-related knowledge is to look at the manufacturing side of the clothmaking equation.

Established in 1960, Meltham-based Lightowlers Yarns is a thriving example of the region’s spinning industry. The family-owned firm is currently run by the second and third generations of Lightowlers – Mark, Peter and Michael – grandson and sons to the original co-founder, Richard.

Mark said: “We’re devoted to passing our diverse spinning skillset further down the Lightowlers’ bloodline. My son – and fourth generation family member – Adam, is also contributing to the business where possible.

Lightowlers sells yarns which it designs and spins on a bespoke basis for many fashion and household furniture brands – as well as Dugdale Bros & Co.

Concluding on the topic, Simon said: “Despite some aspects of modern culture having negatively impacted the industry, it’s also propelled it in other areas.

“Television dramas such as Downton Abbey and Peaky Blinders have raised awareness of sartorial, fine dressing and the increasingly sophisticated made-to-measure garments – giving everyone access to this sector, as well as reigniting many people’s passion for exclusivity and customisation.

“This niche industry in Huddersfield is something we should all take enormous pride in, so let’s erase the doom-and-gloom element, because ultimately, the rest of the world continues to look to our town for the finest cloth in the world – and this trend shows no sign of slowing down.”